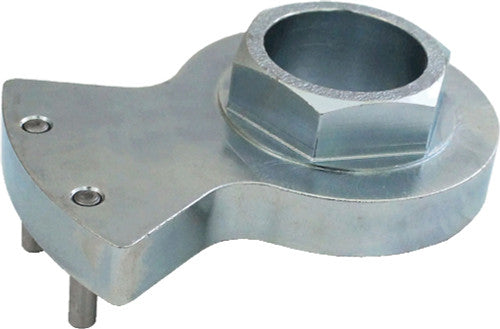

L'article est une scie à tronçonner à changement rapide DEWALT D28715 de 14 pouces. Utilisé pour les outils à main et les organisateurs d'outils, les scies à main. Le produit est fabriqué en Chine. Des coupes transversales rapides et précises sont faciles à exécuter avec la scie à tronçonner DEWALT de 14 pouces dotée de changements de roue sans clé à changement rapide. L'étau exclusif Quick-Lock Vise vous permet de sécuriser rapidement les matériaux, tandis que le puissant moteur de 15 A permet de travailler rapidement les coupes difficiles. Cette scie dispose également de changements de roue pratiques et d'un design portable et ergonomique qui est facile sur votre corps, de sorte que vous pouvez travailler plus intelligemment plus longtemps. Cette scie à découper dispose d'une poignée ergonomique en forme de D qui vous permet de positionner votre main confortablement, réduisant la fatigue de l'utilisateur. et augmentation de la productivité et de la précision. Caractéristiques pratiques pour des coupes précises. Ce sont les détails qui font de cette scie DEWALT un ajout impressionnant et polyvalent à votre collection d'outils. L'étau à verrouillage rapide DEWALT vous permet de serrer une grande variété de matériaux rapidement et en toute sécurité, permettant des transitions plus rapides et une efficacité accrue. Quand vient le temps de faire plus que des coupes à 90 degrés, une clôture pivotante à 45 degrés permet une , coupes d'angle précises. La base en acier de la scie vous permet de souder des gabarits ou des arrêts directement sur la base pour une expérience utilisateur personnalisée qui correspond à vos applications les plus courantes. De plus, le ressort de compression du bras de scie offre un mouvement plus fluide et une durabilité accrue par rapport aux configurations de bras qui utilisent des ressorts de torsion. Un pare-étincelles réglable vous permet de diriger les étincelles loin de votre zone de travail, protégeant à la fois votre corps et vos surfaces de travail. Changements de roue rapides et sans outil et transport facile Lorsque vient le temps de remplacer la roue abrasive, le système de changement de lame à changement rapide permet vous permet de changer les roues sans clé. Ainsi, vous ne perdez jamais un temps précieux à chercher la bonne clé pour terminer le travail. Mesurant seulement 21 pouces de long et pesant 39 livres, cette scie à tronçonner est compacte et portable. Une poignée supérieure intégrée facilite le transport de la scie de votre atelier à votre véhicule ou de votre véhicule au chantier. Pour plus de commodité et de sécurité, une goupille de verrouillage robuste permet de verrouiller la tête de scie en position de transport sans utiliser de chaîne. Cette scie à découper de 14 pouces avec changement rapide est livrée avec un ensemble de garantie DEWALT qui comprend une garantie limitée de trois ans, un contrat de service gratuit d'un an et une garantie satisfait ou remboursé de 90 jours. système.

Caractéristiques

L'article est une scie à tronçonner à changement rapide DEWALT D28715 de 14 pouces

Utilisé pour les outils à main et les organisateurs d'outils, les scies à main

Le produit est fabriqué en Chine

Le puissant moteur de 15,0 A/5,5 hp (puissance maximale du moteur) offre une plus grande capacité de surcharge

Le système de changement de lame Quick-Change permet aux utilisateurs de changer les roues sans clé

Quick-Fence breveté sans outil, guide réglable à 45 degrés permettant des coupes d'angle rapides et précises.

L'étau Quick-Lock permet un serrage rapide sur des matériaux de différentes tailles

Le démarrage progressif prolonge la durée de vie des engrenages et du moteur, poignée ergonomique

Caractéristiques

Fabricant : Dewalt

Numéro de pièce : D28715

Poids de l'article : 44,9 livres

Dimensions du produit : 24 x 15 x 16,5 pouces

Numéro de modèle de l'article : D28715

Est abandonné par le fabricant : Non

Style : Scie à tronçonner

Matière : Acier Inoxydable

Source d'alimentation : électrique filaire

Quantité d'article par paquet : 1

Système de mesure : Métrique

Certification : Certifié sans frustration

Composants inclus : Scie à métaux, Scie à béton, Construction - Scies électriques

Batteries incluses? : Non

Piles requises ? : Non

Description de la garantie : Garantie de remboursement de 90 jours, contrat de service gratuit d'un an, garantie limitée de 3 ans

ASIN : B000HHWWES

Commentaires des clients : 4,7 sur 5 étoiles 395 évaluations 4,7 sur 5 étoiles

Classement des meilleures ventes : n°20,948 dans Outils et bricolage (Voir le Top 100 dans Outils et bricolage)

Expédition nationale : l'article peut être expédié aux États-Unis

Expédition internationale : cet article peut être expédié dans certains pays en dehors des États-Unis. En savoir plus

Date de première disponibilité : 1er janvier 2008

Marque : DEWALT

Dimensions de l'article LxLxH : 24 x 15 x 16,5 pouces