Changing brake pads? Rotors looking a little shiny? Here's the answer! Yes it's a bit time consuming but the results are well worth the effort. The front brakes of my R1100S were pulsing a bit and I initially suspected warped rotors. Hmm. Well, my first thought was just buy some new ones.. How much?!?!

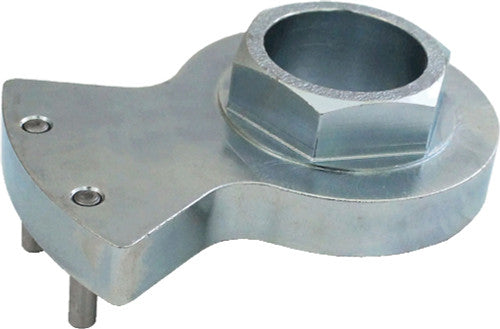

That got me doing some research and discovering according to many rider/mechanics motorcycle rotors rarely if ever warp. One particularly vocal proponent of that view (who also was an R1100S owner) suggested this tool would not only cure the pulsing but would also create a fine cross-hatch pattern typical of new rotors and perfect for bedding-in new pads.

$400 for two new rotors or $35 for the tool? No brainer! Even if the pulsing wasn't cured..

Well, the short story is the pulsing was cured! And the rotors look like new!

Here's the fine print - it does take a fair amount of time.

The outside rotor faces are easy, just raise the front wheel so it can rotate easily, give it a spin and then keep it spinning by applying just the right amount of pressure with the spinning hone. (turns out the correct amount of pressure for optimal honing is the same amount of pressure required to keep the wheel spinning)

The inside faces require removal of the wheel, flipping the rotors over (or installing them on the opposite sides) and then re-installation of the wheel to perform the honing. If your bike has directional rotors (like mine does) when you're done honing you have to repeat the wheel removal, disk switch/flip and re-installation so the rotors are correctly oriented.

All told it was probably a 2 hour process for me. $180 an hour? I'll take that any day!